Tri-Axial Casing Design makes casing design planning quick and easy, this is the latest version of Casing Design which covers both vertical and deviated trajectories resulting in the most flexible and user friendly program on the market, Developed for Microsoft Excel the program is now incorporated with Drilling Engineer

T

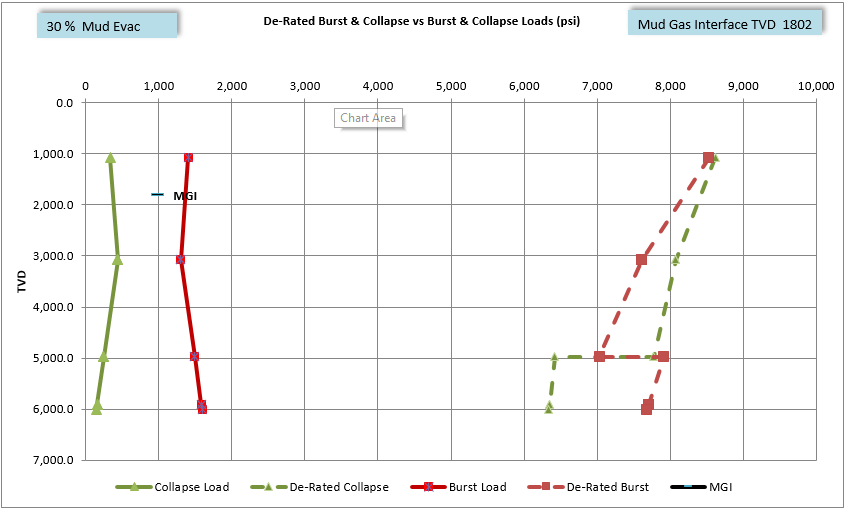

API rated burst strength is de-rated for temperatures from 10 to 600 F° (-12 to 316 C°) Drilling Condition – Gas/oil kick while drilling below the shoe with partial or total mud evacuation (user selects evac percent), with shut in pressurized column of gas/oil to surface and old mud weight gradient behind casing. The old MW that was behind the casing when it was cemented is used for annulus hydrostatic burst calculations and the present MW is used for internal hydrostatic calculations. The user inputs the gas/oil gradient that most closely fits their design for internal pressure gradient.

API rated burst strength is de-rated for temperatures from 10 to 600 F° (-12 to 316 C°) Drilling Condition – Gas/oil kick while drilling below the shoe with partial or total mud evacuation (user selects evac percent), with shut in pressurized column of gas/oil to surface and old mud weight gradient behind casing. The old MW that was behind the casing when it was cemented is used for annulus hydrostatic burst calculations and the present MW is used for internal hydrostatic calculations. The user inputs the gas/oil gradient that most closely fits their design for internal pressure gradient.

Production Condition – 100% mud evacuation with full column of shut in pressured gas/oil to surface and salt water gradient behind casing

Tri-Axial Casing Design calculates Drilling burst loads are calculated assuming a shut in gas/oil kick with Leak off EMW pressure at the shoe and a casing evacuation percent chosen by the user (typically 10 – 40 %).

Production burst loads are calculated assuming a full shut in column of pressured gas/oil (i.e. 100% mud evacuation), with Leakoff EMW pressure at the shoe and a column of salt water behind the casing. .

Collapse Design API rated collapse strength is de-rated for temperatures from 10 to 600 F° (-12 to 316 C°). . The temperature de-rated collapse can also be further de-rated for axial tension if desired.

Drilling collapse loads are calculated assuming the casing has been partially or fully evacuated of mud, (resulting from lost circulation, or a blowout), while drilling below the shoe,

With a non-pressured column of gas/oil to the surface (i.e. atmospheric pressure at the surface) and a full column of old MW behind the casing. The user inputs the gas/oil gradient that most closely fits their design for internal pressure gradient.

.Production collapse loads are calculated assuming 100% mud evacuation with an un-pressured column.of gas/oil to the surface.

The old MW that was behind the casing when it was cemented is used for annulus hydrostatic collapse calculations. The user inputs the gas/oil gradient that most closely fits their design for internal pressure gradient.

Cementing Collapse loads, are calculated with applicable hydrostatic columns of mud and cement slurries outside the casing and displacement fluid column inside the casing.

The small hydrostatic difference of the cement in the shoe joints is ignored and displacement fluid is assumed to the shoe TVD. Cementing collapse is typically a concern with big OD conductors and surface casings.

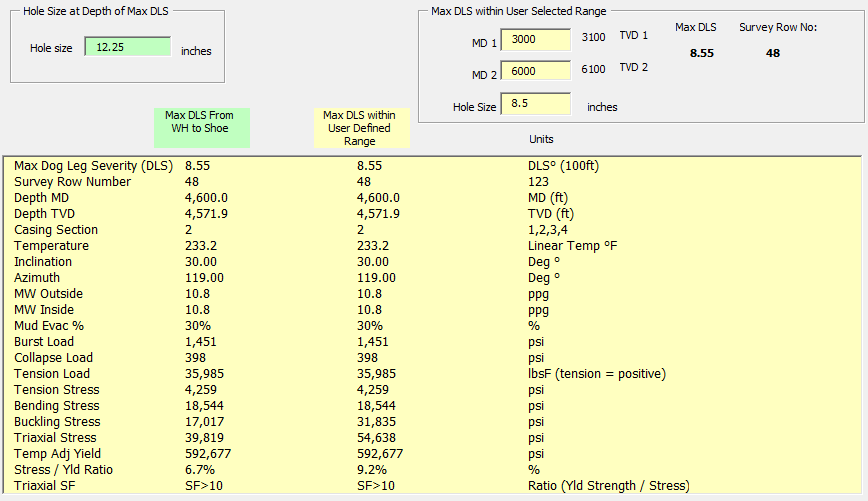

Tensile Design API rated tensile strengths (body and joint), are de-rated for temps 10 to 600 F (-12 to 316 C). . Drilling and Production Casings are calculated with the same assumptions.

Tensile analysis considers the total hanging weight of the casing as it is being run in the hole. The user selects Vertical or Directional tensile analysis to calculate tensile loads assuming buoyant weight of steel in a mud filled hole. . Buoyancy factor = (65.4-MW)/65.4

Vertical tensile load assumes casing hanging in a vertical hole with drag forces ignored.

Directional tensile load assumes the true vertical (TVD) length, of the casing at any specified depth (i.e. axial tensile load), with drag forces ignored. . Directional program calculates TVD’s from user input survey data.

Tri-Axial Casing Design includes a combination of csg and Liner installation , the new version of Casing Design now includes liner overlap calculations

Tri-Axial Casing Design can be linked to Well Trajectory and Azimuth Closure planned in Well Plan

The program covers both Vertical, Directional designs for On Shore, Shallow Water Offshore, Deep Water Off Shore . Feet or Meters, temperature de-rating factors, cementing safety factors Burst, Collapse, Tension Safety Factors can be API or user defined.

This Tri-Axial Casing Design video clip will show you how to incorporate a single or multiple liners in your design, you can design one cemented in place casing string and up to 3 liners or several combinations

Tri-Axial Casing Design includes 4138 different joints of casing to choose from plus custom editable casing database this allows the input of unlimited custom casing sizes to be added to the database.

To enlarge the following images right click and select view in new tab

Temp De-rated tensile strength vs Tension Load with 3 liners installed

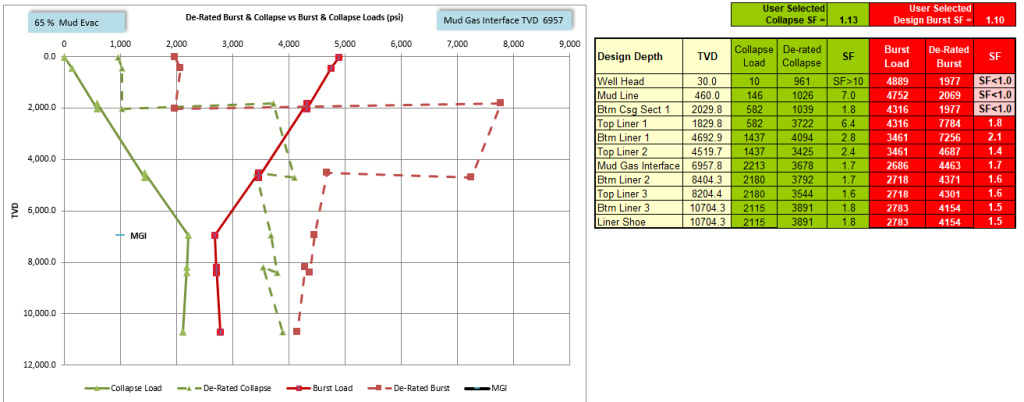

Temperature de-rated burst and collapse loads with 3 liners installed

Data tables indicate safety factors below designated design requirements

Yield strength de-rating factors vs temperature at TVD charts indicate shallow water location

You can import the planned trajectory build with Well Plan

How to import a saved survey

Well Plan is complimentary to Tri-Axial Casing Design and now included with Drilling Engineer

Summary

- De-Rated Burst and Collapse due to temperature affect vs. Burst and Collapse loads (psi) at the top and bottom of up to 4 different rated casing sections, or combination cemented in place casing plus up to 3 liners

- For example:

- Cemented casing plus Liner1 with three different sections (spec)

- Casing plus Liner 1 two different sections (spec) plus Liner2

- Upper casing Liner1, Liner2, Liner3

- In place casing Liner1, Liner2 plus two different sections (spec)

- Completely adaptable to any combination of casing and liners

- De-Rated Tensile Strength vs. Tensile Loads (lbs.) at the top and bottom of up to 4 different rated casing sections

- Yield Strength De-Rating Factors vs. Temperature in °F & °C

- Vertical Section View chart

- Plan View chart

- Dog Leg Severity (100’ or 30 Mtrs) chart

- Export and Email reports

The program covers On Shore, Shallow Water Offshore and Deep Water Offshore calculations

Download a free trial of casing Design from this link

You can also make a secure purchase from this link